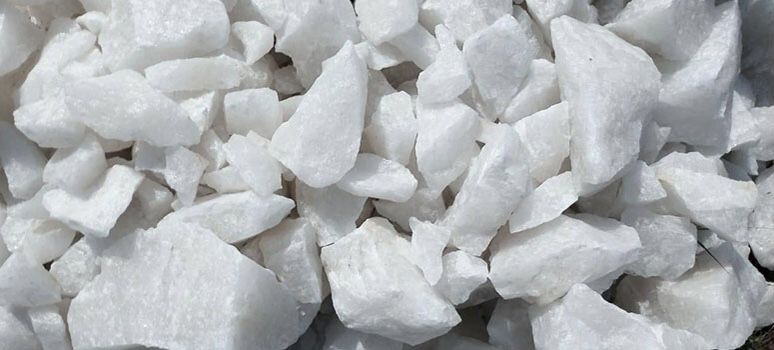

Quartz Lumps & Silica Sand

Quartz powder, specifically fused and synthetic, is a highly versatile material with various applications across different industries. It is primarily composed of silicon dioxide (SiO2), offering exceptional durability and hardness, making it suitable for a wide range of uses. The product is available in a powdered form, which is primarily used in abrasives, ceramics, and manufacturing, and has found recent applications in renewable energy sectors such as solar panel production.

Key Characteristics and Applications:

- Abrasives: Ground quartz serves as a key component in abrasive materials used for stonecutting, sandblasting, and glass grinding.

- Porcelain & Ceramics: Powdered quartz is integral in the production of porcelain and various ceramic products, owing to its hardness and inert chemical properties.

- Scouring Soaps & Sandpaper: Due to its abrasive properties, quartz powder is often used in scouring soaps and sandpaper products.

- Wood Fillers: Quartz is used in wood fillers for both its physical properties and ability to provide a smooth finish.

- Solar Panels: Recent innovations have seen powdered quartz being employed in the production of solar panels, where its high purity and chemical stability are critical.

Types of Quartz:

Quartz exists in several forms, each with unique characteristics. Some of the most common varieties include:

- Amethyst

- Citrine

- Smoky Quartz

- Rose Quartz

- Rock Crystal

- Milky Quartz

- Ametrine

These types are distinguished by their colors, crystal structures, and inclusions, though the basic mineral structure of SiO2 remains the same

Additional Uses:

- Sandpaper & Abrasives: Crushed quartz is used as an abrasive in sandpaper, while silica sand finds applications in sandblasting.

- Whetstones & Millstones: Whole quartz-based sandstones are still used to produce whetstones, millstones, and grindstones.

- Optics: Fused quartz, or silica glass, is used in optical applications due to its excellent ability to transmit ultraviolet light.

Chemical Composition:

- SiO2 (Silicon Dioxide): 99.1%

- Al2O3 (Aluminum Oxide): 0.62%

- K2O (Potassium Oxide): 0.64%

- MgO (Magnesium Oxide): 0.26%

- Fe2O3 (Iron Oxide): 0.18%

This high purity of SiO2 makes quartz powder highly effective in a range of demanding industrial applications, where high strength and low impurity levels are required.

Conclusion:

Quartz powder (fused and synthetic) is a highly versatile and valuable product used across various industries, from abrasives and ceramics to cutting-edge applications in solar technology. Its chemical stability, hardness, and diverse range of applications make it a sought-after material in both traditional and modern industries